The Original Cylindrical Valve Gate by männer.

männer has been developing valve gate hot runner systems for fifty years. männer's "cylindrical valve gate" is sophisticated hot runner technology delivering the best possible gate quality. While our system is copied by many, only the original lives up to its promise.

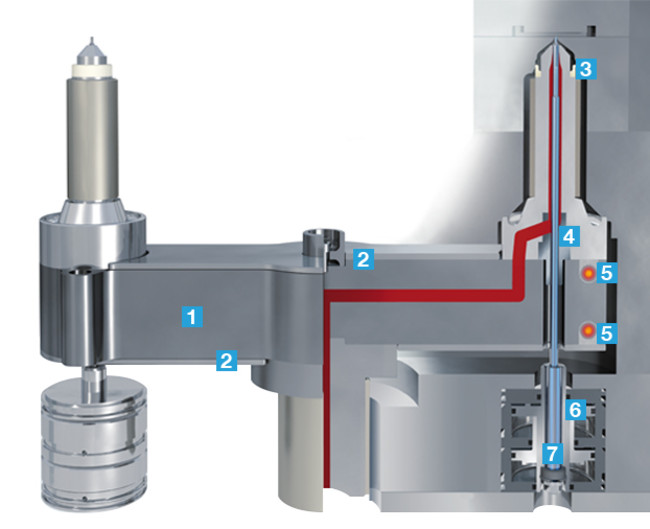

- HOT RUNNER MANIFOLD

- Temperature-independent sealing function

- Leakproof

- Naturally balanced melt flow

- No stagnation areas

- Suitable for color changes

- Hardened manifold block

- INSULATION PLATE

- Reduces thermal radiation

- INSULATION RING

- Thermal insulation

- Nozzle centering

- Sealing function

- VALVE PIN BUSHING

- Integration of valve pin guide bushing into nozzle to prevent bending of pin during thermal expansion of manifold

- Replaceable

- TUBULAR HEATING ELEMENTS

- Long life

- Cast in heat conductivity compound for uniform temperature distribution

- PNEUMATIC UNIT

- Tandem cylinder: small unit size with high closing force

- Clean room proven

- VALVE PIN

- Installation/removal of valve pin possible with system already installed

The Original Precentered Cylindrical Valve Gate by männer.

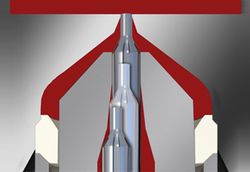

During the closing movement, the valve pin is first precentered by an angled guide area and then positioned perfectly in the gate orifice by means of a cylindrical guide.

Nozzle and valve pin are designed to provide high performance, zero gate vestige, and long life. The cylindrical valve gate has been patented by männer.

Video

Cylindrical Valve Gate

We have custom-developed a valve gate system for stack molds.

- Injection points lie on a single axis

- Split snorkel provides room for handling systems

- Minimal assembly height of middle platen

- Direct injection with männer valve gate hot runner technology

We deliver your hot half with individually controlled pneumatic units or with a pin actuation plate furnished with a pneumatic or electrical drive depending on the application involved.

Pneumatic individual drive

- Proven and easy to maintain

- High-speed opening of the pins positively impacts the cycle time

Pneumatic plate actuation

- Ideal for synchronized filling of high-cavitation molds

Electrical plate actuation

- Ideal for synchronized filling of high-cavitation molds

- Customizable path profile

- Variable positioning of pins

Learn more about the electrical plate actuation männer e-plate

Videos

above Valve pin actuation with tandem pneumatic system

below Electrical plate actuation männer e-plate