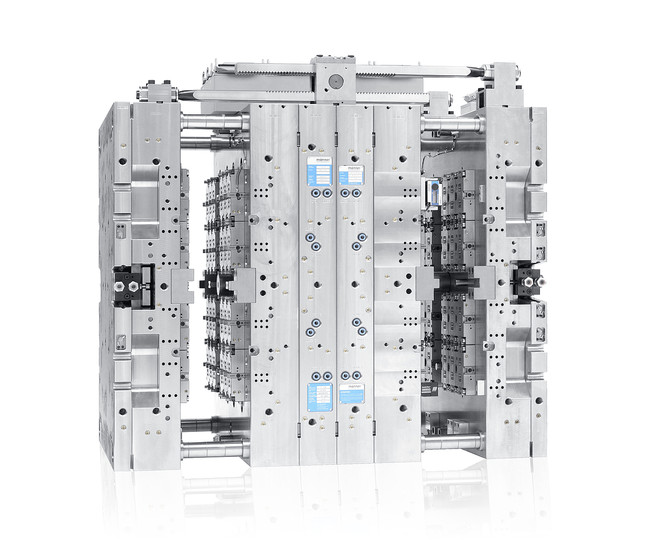

Molds For Large-Volume Production

männer high-precision molds are extremely durable, high-performance molds specifically designed for large-volume production of precision injection-molded parts.

We develop our high-precision molds with an eye on part-to-part consistency and reproducibility, which are essential to automated downstream processing of the injection-molded parts.

- Repetition accuracy

- Long life

- Optimized temperature control for short cycle times

- Easy maintenance with männer's "easy-change" system

- Thin-wall technology

Download Brochure High Precision Molds - System Solutions